- NAN YA

- PRODUCT

- CONTACT

Nan Ya Plastics Corporation

As a subsidiary of FORMOSA GROUP, NAN YA Plastics Corporation produces all petrochemical and electronic products such as plastic materials, chemicals, and electronic materials. We, KIMS, have been working closely as Korean Agent since 1995, and supplying CCL & PPG products to the Korean market stably.

Promotion and Collaboration with NAN YA

Nan Ya Plastics Corporation Summary

- Year of Establishment : 1958

- Number of Employees : 12,904(2020)

- Annual Sales Volume : about US$1,418million

- Production Capacity of CCL & Laminates

- Copper Foil : 90,000ton/year (World ranking No. 2)

- Glass Yarn : 196,000ton/year (World ranking No. 1)

- Glass Fabric : 56,000,000meter/year (World ranking No. 1)

- Epoxy Resin : 457,000ton/year (World ranking No. 1)

- CCL : 6,530,000shts/year (World ranking No. 2)

Our Production Capacity

| YEAR CAPACITYPRODUCT | UNIT | Capacity Increasing (2015~202018) | Worldwide Ranking |

REMARKS | |||

|---|---|---|---|---|---|---|---|

| COPPER CLAD LAMINATE | K SHT / MONTH | 5,780 | 5,880 | 6,030 | 6,030 | No. 2 | 13% FR-4 based global market share. Completed verticle integration to ensure superior QCDS. |

| EPOXY RESIN | K TON / YEAR | 457 | 457 | 457 | 457 | No. 1 | 17% global market share. Capability to sufficiently supply all types of high function resin systems, incld. Halogen free · high Tg and advanced low Dk resins. |

| GLASS FABRICS | K MTR / MONTH | 46,500 | 50,000 | 53,500 | 56,000 | No. 1 | 30% global market share. Anti-Caf and ultra thin capability. Largest supplier to Japanese market. (>50% market share) |

| COPPER FOIL | K TON / MONTH | 6.2 | 7.5 | 7.9 | 8.0 | No. 2 | 19% global market share. Aresnic free copper foil. Very low and no profile production capability. |

| GLASS YARN | K TON / YEAR | 196 | 196 | 196 | 196 | No. 1 | 28% global market share. Outstanding hollow fiber control. Ultra fine yarn capability. Low Dk glass development. |

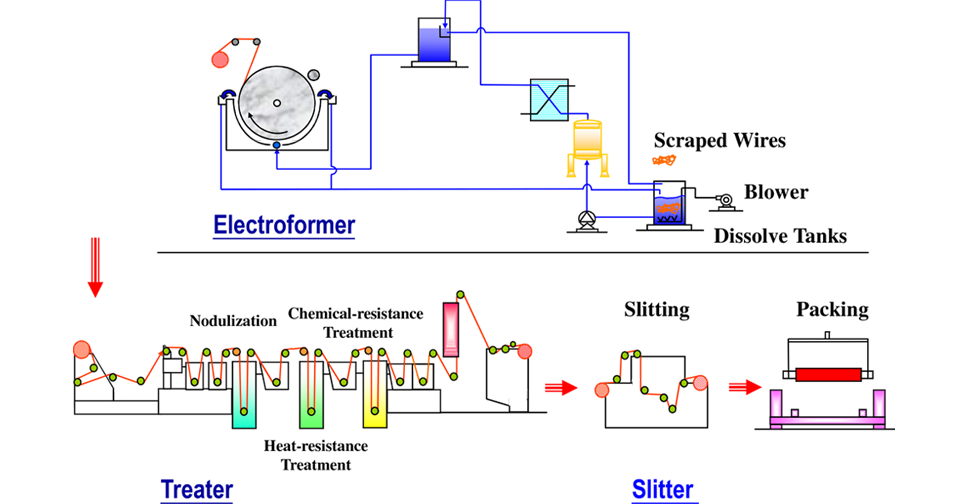

Production Process

(Copper Foil)

| Process | Electroformer | Treater | Slitting | Packing |

|---|---|---|---|---|

| Process Detail | Electrolytic Copper Foil is produced through a titanium skin drum by copper wire melting | Copper Foil type (Roughness, Heat-, Oxidation Resistance) is determined by Chemical Treatment | By Slitting Process, automated Appearance Inspection and Second Inspection can be made additionally | Packing Process for Delivery/Shipment |

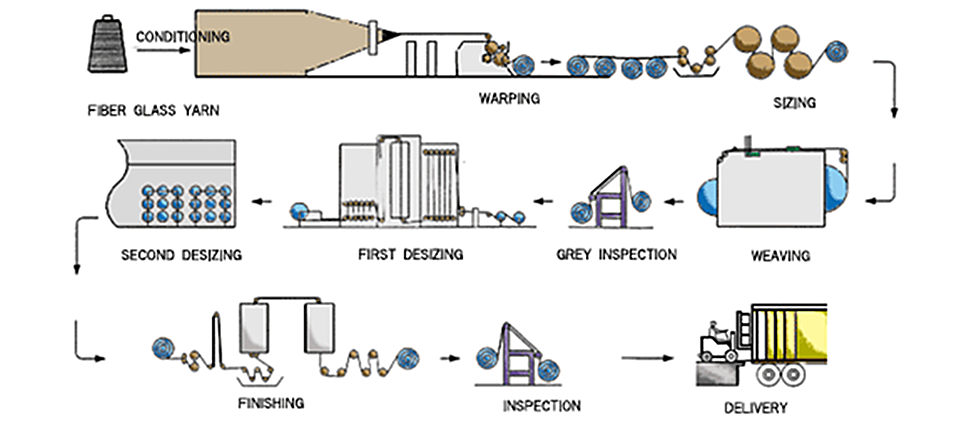

Production Process

(Glass Fabric)

| Process | Warping | Sizing | Weaving | Grey inspection |

|---|---|---|---|---|

| Process Detail | Weave fabric in the WARP direction of Yarn | Coating is made before the fill direction weaving to prevent abrasion | Weave fabric in the FILL direction of Yarn | Inspection about Weaving condition |

| Process | 1st Desizing | 2nd Desizing | Finishing | Inspection |

|---|---|---|---|---|

| Process Detail | Through Heat Treatment, remove 90% of Sizing Coated Material | 2nd Desizing Process to remove residual substances in over 300°C oven for 3days | Divide Glass Fabric for PPG production process or Industrial products | Outgoing Inspection |

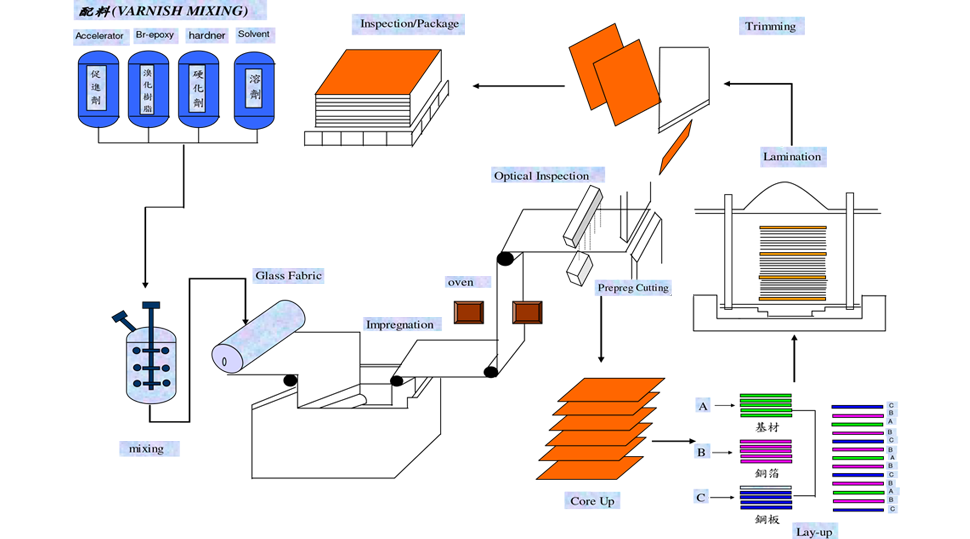

Production Process

(CCL & PPG)

| Process | Mixing | Treater including impregnation | Core up | Build up |

|---|---|---|---|---|

| Process Detail | Mixing Process in A- stage (liquid) status with epoxy, hardener, solvent, etc. | B-Stage(half curing) product is made through resin contents control - Fabric Impregnation Process. | Composed Core Specification is decided | Build up process before Press work |

| Process | Lamination | Trimming | Inspection /Package |

|---|---|---|---|

| Process Detail | Lamination Process by Press Machine | Trimming Process of laminate’s outline | Inspection of product/Packing Process before Delivery/Shipment |

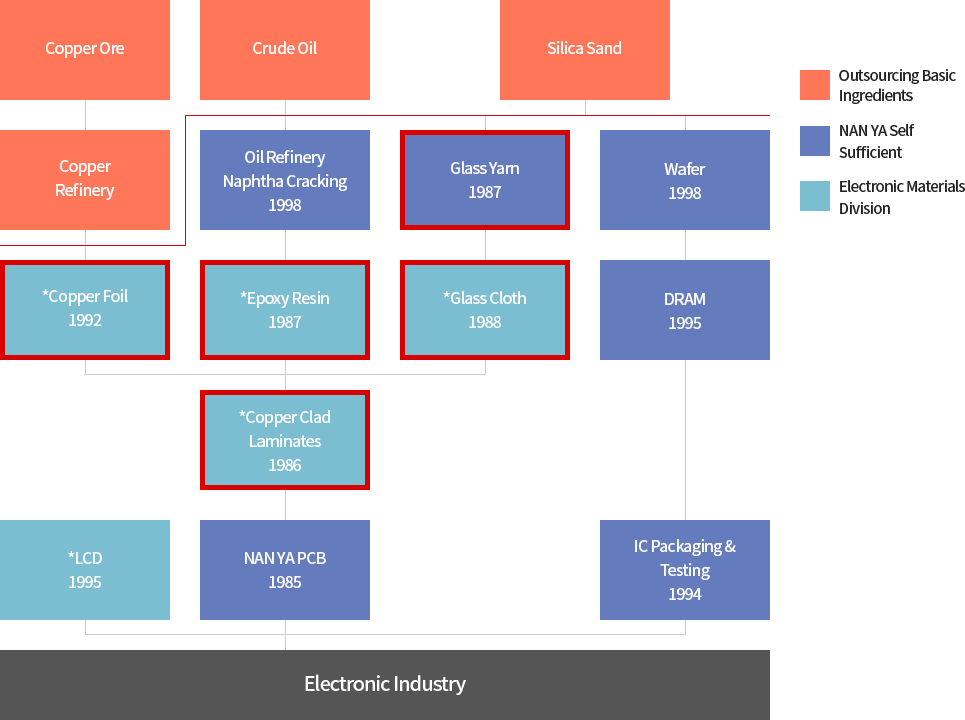

Vertically integrated Production Management of Raw Materials for NAN YA products

Vertically integrated Production Management of Raw Materials for NAN YA electronic materials production

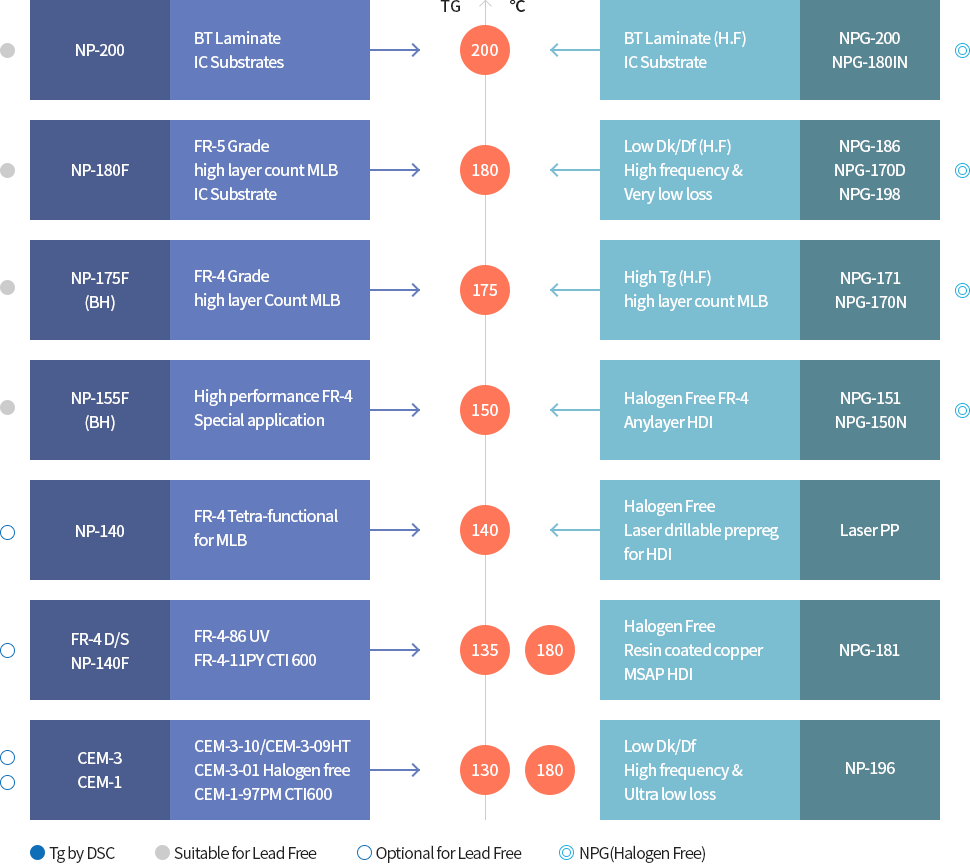

INTRODUCTION OF MAIN PRODUCTS BY CATEGORY

| PRODUCT CATEGORY | MAIN PRODUCT NAME PER CATEGORY |

|---|---|

| Home Appliance /Industrial PCB | NP-140F, NP-140, FR-4-11PY CTI 600 |

| Automotive | NP-155F, NP-175F(BH), NPG-180BH |

| HDI | NPG-151, NPG-181 |

| HLC(EX.Network) | NPG-170D, NPG-186, NPG-198 |

| PKG | NPG-181, NPG-200(W) |

Development of new raw materials for application to each product category is in progress.

Raw Material Site Link

Certificate Status

For more information, please contact with Raw Material Sales Team

UL Certificate Link

UL Find Link File Search Number : E98983Regularly ISO 9001,14001,OHSAS 18001, MS941-01 REPORT, RoHS, UL, Hazardous Substance Analysis Data, etc. are updated.

Growing OEM Customer Base

Network & Computing

Automotive

Mobile Communications

Multimedia & Consumer

Raw Material Sales Team Contact Information

-

NAN YA products inquiry

- Tel 032-511-9301~5

- Fax 032-511-9388

- July Kim july@pcbtest.co.kr(ext. 301)

- June, Oh june@pcbtest.co.kr(ext. 303)