- VEGA

- TCF

- LENSTAR

VEGA CNC TECHNOLOGY (SUZHOU) CO.,LTD Company Introduction

VEGA CNC TECHNOLOGY (SUZHOU) CO.,LTD., is a high-tech enterprise that provides digital intelligent special equipment, and integrates the process of R&D, manufacture, sales and service.

They dedicate to the R&D of precision CNC, intelligent manufacturing, robot, industrial laser, visual inspection, IoT and software design, which are widely used in semiconductor, PCB, SMT, 3C high precision metal processing and other industrial fields.

History of Development

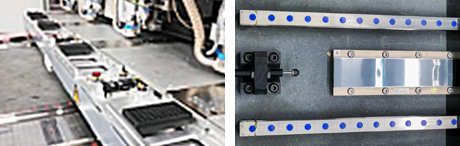

Equipment Characteristics

-

Easy and stable Sieb & Meyer control system

-

High Precision & Speed, None friction X, Y, Z Axis Linear Motor

-

Fast speed response and stable moving from the application of a granite body & aeronautical lightweight table material

-

CBDT and Non-contact tool detection to improve the precision and avoid loss of tools

PCB Equipment Main Product

| PCB Normal | PCB Blind | CCD Depth-Controlled | |

|---|---|---|---|

| Routing Machine | Ultra R2L Ultra R4/L Ultra R6/L |

Ultra R2DL Ultra R6D/L |

Multi R2L Multi R6L |

| Drilling Machine | Super D2CMSL Super D4CMS/L Super D6CMS/L |

Multi D2CMSL Multi D6CMSL |

-

VEGA drill machine Super D6CMS drill machine

- Selectable from 2, 4, 6 Axis

* Applicable large size working table

Main technical parameter

Velocity of X/Y 85m/min Velocity of Z 50m/min Spindle Speed 200krpm (160krpm available) Tool Magazine 6×300 Positioning Accuracy ±0.004mm Repeatability Accuracy ±0.0025mm Drilling Accuracy ±0.8mil(VEGA Condition) Depth Accuracy 6×560mm×700mm (22''×27.6'') Working Area 6×560mm×680mm (22''×26.8'') Dimension 4230mm×1917mm×1580mm Weight 12600kg - Selectable from 2, 4, 6 Axis

-

VEGA Router machine Ultra R6 Router

- Selectable from 2, 4, 6 Axis

*Applicable large size working table

Main technical parameter

Velocity of X/Y 30m/min Velocity of Z 15m/min Spindle Speed 60krpm Tool Magazine 6×11 Positioning Accuracy ±0.005mm Repeatability Accuracy ±0.0025mm Drilling Accuracy ±2mil(VEGA Condition) Depth Accuracy 6×560mm×760mm (22''*29.9'') Working Area 6×560mm×745mm (22''*29.3'') Dimension 4230mm×1917mm×1530mm Weight 10600kg - Selectable from 2, 4, 6 Axis

-

VEGA Optical drill machine Super D6CMS drill machine

- Selectable from 2, 4, 6 Axis

* Applicable large size working table

Main technical parameter

Velocity of X/Y 85m/min Velocity of Z 50m/min Spindle Speed 200krpm (160krpm available) Tool Magazine 6×350 Positioning Accuracy ±0.004mm Repeatability Accuracy ±0.0025mm Drilling Accuracy ±0.8mil(VEGA Condition) Depth Accuracy ±0.025mm(VEGA Condition) Working Area 6×635mm×745mm (22''×26.8'') Dimension 4860mm×2000mm×1690mm Weight 15600kg CCD DOF(Depth of Focus) 2mm CCD Alignment accuracy ±5㎛ CCD FOV(Field of View) 6.8*5.1mm - Selectable from 2, 4, 6 Axis

Suzhou Top Creation Machines Co., Ltd. Company Introduction

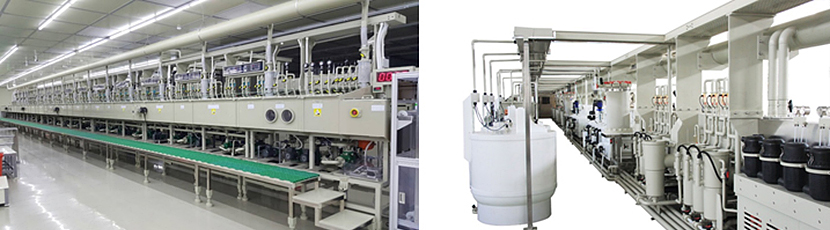

Suzhou Top Creation Machines Co., Ltd.(TCF), located in Suzhou is specialized in manufacturing and designing PCB, FPC, Flip Chip Substrate, Touch Panel and Photovoltaics wet process equipment. The parent company C-SUN has 50years of manufacturing experience which fills the spirit and strength into the advance of TCF. In accordance with our concept “continually improving, constantly innovating, unceasingly enterprising, Integrity and Responsibility”, TCF creates high-performance, high reliability, high-quality energy-efficient equipment and components for valuable customer.

History of Development

Non-Contact Desmear Equipment Characteristic

Desmear & PTH Equipment Characteristic

-

Conveying System

Quick wearing part’s material is Peek(ex. Bush).

And peek offers better chemical-, heat-, Abrasion-, Corrosion-resistant character.- Roller Interval : 25mm disk

- Roller : Ø33mm

-

SWELLER/PERMANGANIC ACID

-

PATENTED WATER RINSE PROCESS

Safe and optimal Filter design is adapted

in the pump suction side ,cartridge or filter bag. -

HOT WATER SYSTEM

For safety and maximized energy saving,

hot water system is adapted for heating.

Other Products Link

- Horizontal Developing,Etching,Stripping Line (DES) DES Line

- Horizontal RTR Horizontal Copper Plating RTR FPC Wet Process Equipment

- Horizontal Immersion Tin Line Immersion Tin Equipment

- Horizontal Brown Oxide Line Brown Oxide Equipment

- Horizontal Copper Reduction Equipment Copper Reduction Equipment

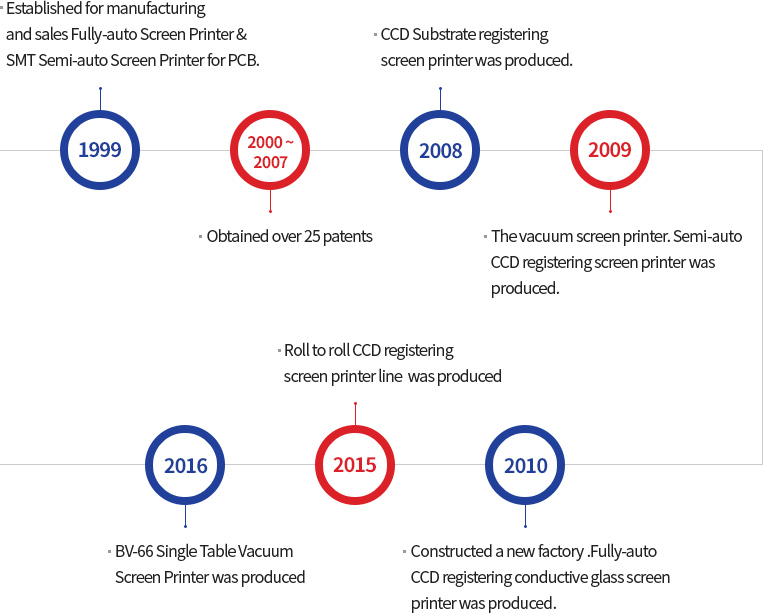

LENSTAR PRECISION MACHINERY CO.,LTD Company Introduction

Since incorporating in 1999, LENSTAR PRECISION MACHINERY CO., LTD. has manufactured fully-auto screen printer. Semi-auto screen printer. Related equipment for screen printing. Customization for precision machine and experts in LCD, PCB, SOLAR ENERGY, AUTOMOBILE GLASS, etc. Their abundant experience and knowledge in Screen Printing Equipment over ten years will provide best services to clients.

History of Development

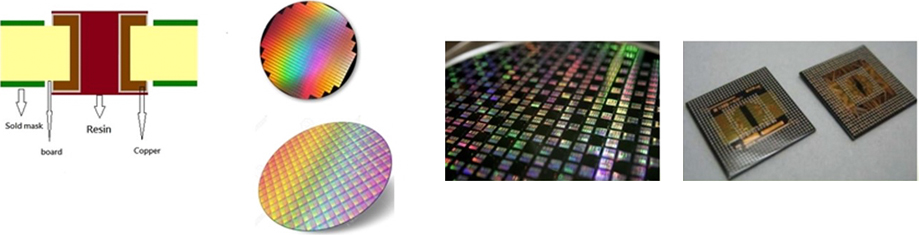

Equipment Introduction

Equipment Characteristic

- Screen Printing => Minimize of Printing Ink’s Consumption

- Not changing the existing manufacturing process, possible to do hole plugging as option

- Input setting value from Touch Screen

- Printing & Electric Motor can be controlled precisely by Servo Control

- Cleaning for Ink Extrusion Tank and Pipe is not required